Contributing author: Elizabeth A. Mengelt

PDMS may be poured into a hollow spherical mold with a small hole in the top. After curing and removing the mold, the PDMS has the shape and behavior of a rubber ball. The mechanical properties of the ball can be controlled by manipulating the properties of the uncured PDMS. For example, increasing the ratio of curing agent to base creates more crosslinking in the polymer and makes a more rigid elastomer. The increased rigidity of the elastomer allows the PDMS ball to bounce higher.

Materials

Procedure

Figure 1. Recommended mold for making the bouncing PDMS ball.

Explorations

The movie below shows 2 PDMS balls being dropped. Which ball was made from the following ratios of curing agent to base: 1:5 and 1:15? Run the movie to find out.

Figure 2. The "bounce" of PDMS varies with its composition.

The ball on the left has a ratio of 1:5: it bounces higher, because it is more rigid due to substantive crosslinking. The ball on the right has a ratio of 1:15: it bounces less; as it is more flexible due to less crosslinking.

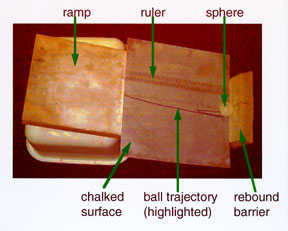

Measuring the vertical rebound of the spheres from a hard surface is very difficult. For more quantitative measurements, we have found that rolling the spheres down an inclined plane into a rigid barrier is a convenient way to study the properties of the spheres, Figure 3. When the ball rebounds from the barrier, which is perpendicular to the surface of the plane, it rolls back up the ramp. Though it is still difficult to visually track the spheres, it is possible to trace their path by dusting the surface of the ramp with chalk dust. Dusting dark cardboard lying on top of the inclined plane works well. From the mapped path the maximum bounce height along the ramp can be directly measured.

Figure 3. Recommended inclined plane assembly for this lab.

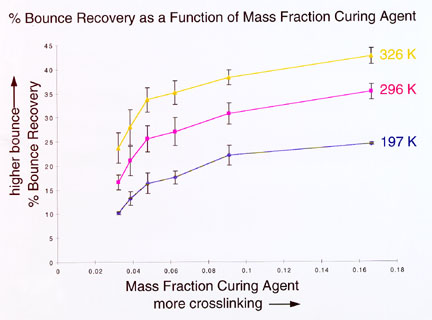

Spheres containing different degrees of crosslinking or at different temperatures may be rolled down the ramp. The spheres may be heated in the drying oven or chilled with ice water or dry ice (liquid nitrogen will bring the spheres below their glass transition temperature). The spheres must be immediately rolled down the plane after heating or cooling before they return to room temperature. A warm sphere will bounce higher than a cool sphere of the same base:curing agent ratio (same degree of crosslinking). Figure 4 shows the results of a study of percent bounce height as a function of degree of crosslinking and temperature.

Figure 4. Percent bounce recovery as a function of mass fraction

curing agent.

Return to the PDMS Main Page

Experiment 1 - The "Initial" Stamp

Experiment 2 - A Flexible Diffraction Grating

Experiment 4 - Surface Treatment of PDMS