Experiment 1 - The "Initial" Stamp

The PDMS stamp can be used to transfer many small complex patterns. This experiment

may be used to learn about the general idea of the stamp fabrication process

and properties.

Materials

- Dull pencil

- Aluminum foil

- Glass slide

- Convection oven capable of reaching 130º C

- Sylgard Elastomer 184, obtained from Ellsworth

Adhesive Systems

- Thick-walled tube mold (~ 1 cm I.D. x ~ 3 cm long). A recommended mold is

a standard taper 24/40-to-10 Pyrex adapter.

- Ink pad or markers

Procedures

- Take a smooth piece of aluminum foil and place it on a somewhat soft surface

like a stack of paper. Using a dull pencil or a ball-point pen, print letters

such as your initials onto the foil surface, Figure 1. Deeper letter

imprints make better stamps, but DO NOT open holes in the foil with the writing

instrument. It may take some practice to obtain uniformly deep lettering.

Figure 1. Impressing initials into aluminum foil.

- Place the foil onto a solid, heat-resistant flat surface such as a glass

slide and carefully place the glass tube over the foil. Be careful not to

flatten the engraved lettering with the mold while it is being positioned.

A recommended mold is a standard taper 24/40-to-10 Pyrex adapter, Figure 2.

Figure 2. Recommended mold for making the "initial" PDMS

stamp.

- Pour the freshly mixed PDMS (~1:10 ratio of curing agent to base) into the

mold to a depth of approximately 1 cm (typically 1 g will be sufficient for

the mold previously mentioned) and set aside for 15 minutes to reduce the

amount of bubbles and PDMS clinging to the sides of the mold. After curing

at 130º C for 30 minutes and cooling, slowly peel the foil away from

the PDMS and mold. Then carefully remove the PDMS from the mold by pressing

on the PDMS at a point where it meets the inside mold walls on the end opposite

the lettering. Repeat this process while moving around the inside wall until

the PDMS pops free of the mold. Excess cured elastomer may be removed carefully

with a razor blade.

Explorations

The stamp may be inked by an ink pad or even by markers, Figure 3. Try squeezing

the stamp during ink transfer to paper and observe what happens to the size

and shape of the letters, Figure 4.

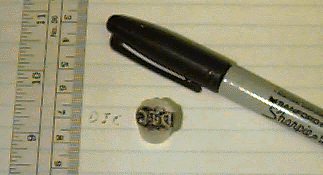

Figure 3. Print from "initial" stamp inked with permanent

marker. The length of the "J" (the middle letter of DJC) in the

printed image is four millimeters.

Figure 4. Compressing the "initial" PDMS stamp (direction

of compression indicated by arrows). The length of the "J" in the

printed image (the middle letter of DJC) has increased to five millimeters.

Return to the PDMS Main Page

Experiment 2 - A Flexible Diffraction

Grating

Experiment 3 - Bouncing PDMS Balls

Experiment 4 - Surface Treatment of PDMS

Exploring

the Nanoworld |

MRSEC Nanostructured Interfaces

Copyright © 2006 The Board of Regents of the University

of Wisconsin System.