-

Experiment 2 - A Flexible Diffraction Grating

PDMS may be cured in contact with the raised surface of a diffraction grating,

copying the surface features and making the polymer slab a flexible, transparent

diffraction grating. The polymer properties of this grating may be used in a

number of experiments.

Materials

- Flat, smooth glass or metal plate

- Convection oven capable of reaching 130º C

- Razor blade

- Square metal frame, such as a ~3 cm length of square pipe with sides of

~2.5 cm

- Sylgard Elastomer 184, obtained from Ellsworth

Adhesive Systems

- Pocket laser

- A disposable diffraction grating, such as # E39,502 from Edmund

Optics (the grating surface features are opposite the Edmund Scientific

logo) or an Optical Transform Slide from the Institute

for Chemical Education, or ICE, (the grating surface features are opposite

the "ICE" logo).

Figure 1. Disposable diffraction gratings from Edmund Scientific (top) and

The Institute for Chemical Education (bottom).

Procedure

- Place the grating, feature-side up, on the metal plate. Remove the frame

from the diffraction grating. Place the metal frame over the grating.

Figure 2. Recommended mold for making the flexible diffraction

grating.

- Prepare a ~3 g batch of PDMS; we recommend a ratio of curing agent to base

of between 1:10 and 1:15. After mixing the PDMS components thoroughly, set

the mixture aside for 15 minutes to allow bubbles to rise out of the PDMS.

Fill the diffraction slide/square frame assembly with PDMS and again set aside

for 15 minutes to allow bubbles to rise out of the PDMS.

- Place the asssembly into an oven at 130º C to cure the PDMS for 20

minutes. Remove the assembly and allow it to cool to room temperature. Carefully

remove the PDMS from its frame.

Explorations

- Place the PDMS diffraction slab in front of a laser beam (WARNING: Lasers

are high-intensity light sources; please follow recommended usage instructions)

with the beam entering from the side opposite the diffracting surface. The

laser beam diffracts.

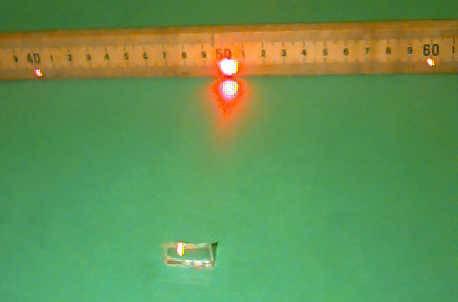

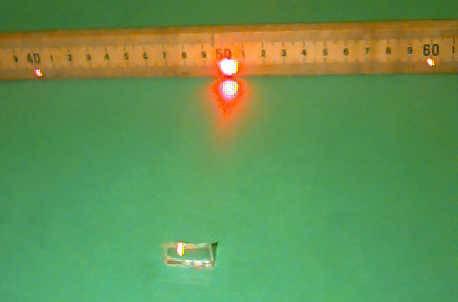

Figure 3. Diffraction of a laser beam with the PDMS slab.

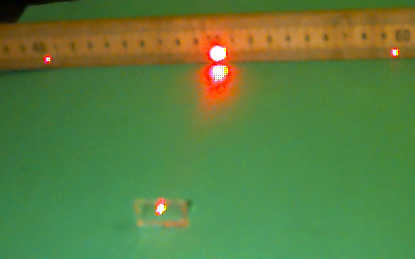

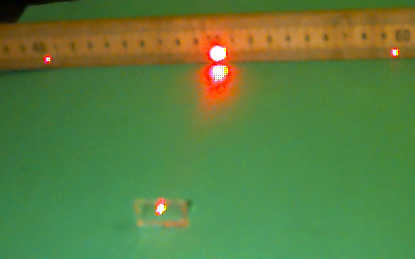

- Distorting the PDMS slab will distort the diffraction pattern. Shown below

is a square diffraction pattern generated by a square array of features on

the surface of a PDMS slab. Would you predict the diffraction pattern to stretch

or contract vertically as the slab itself is stretched vertically?

Figure 4. Distortion of a diffraction pattern by distortion of

the diffraction grating.

As the diffraction grating is stretched in a particular direction, the diffraction

pattern contracts in that same direction. This is referred to as the reciprocal

lattice effect and is a result of the wave nature of light.

Squeezing the diffraction slab fabricated above results in an increase in

spacing between the diffraction spots.

Figure 5. Squeezing a diffraction grating.

- Beside mechanical distortion, spacings between features on PDMS diffraction

gratings may be changed by other methods. PDMS has a high coefficient of thermal

expansion, so heating the grating (i.e. by heating it on a hot plate, for

a short time) will cause the diffraction pattern to contract as feature spacings

increase.

Figure 6. Heating a diffraction grating.

- PDMS may also be swelled as solvents such as toluene are absorbed by the

polymer. Solvent swelling of the grating will cause the diffraction pattern

to contract as feature spacings increase.

Figure 7. Solvent swelling a diffraction grating.

Return to the PDMS Main Page

Experiment 1 - The "Intial"

Stamp

Experiment 3 - Bouncing PDMS Balls

Experiment 4 - Surface Treatment of PDMS

Exploring

the Nanoworld |

MRSEC Nanostructured Interfaces

Copyright © 2006 The Board of Regents of the University

of Wisconsin System.