An Electrochromic Prussian Blue Nanolayer Pixel

Precedure developed by Derek Keefer and George Lisensky

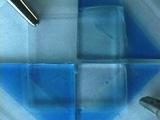

An approximately 200 nm thick layer of Prussian Blue, Fe(III)4[Fe(II)(CN)6]3, on conducting glass can be used to make an electrochromic pixel. Electrochromic displays, where an electrochemical redox reaction changes the pixel state, do not need constant application of power. Such pixels have promise in electronic books where high contrast and low power consumption are important.

| Procedure | Wear eye protection |

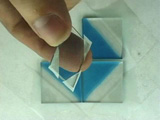

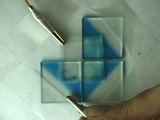

K3[Fe(III)(CN)6] is electrochemically reduced at a glass electrode to produce K4[Fe(II)(CN)6] which reacts with Fe(III)Cl3 in solution to give insoluble Prussian Blue, Fe(III)4[Fe(II)(CN)6]3, on a conducting glass electrode. Use the procedure for production of Electrochromic Prussian Blue Thin Films to produce a 150-200 nm thick layer. Identify the conducting side of the glass squares by using a multimeter to measure resistance. The conducting side will have a resistance of 20-30 ohms. Add two strips of tape to the conducting side of a glass square to serve as a spacer. Assemble the two glass plates with conducting sides together, but offset so that glass extends beyond the sandwich. Clamp the plates together. Clamp an aligator clip to the protruding end of each glass plate. To do this experiment as a demonstration, place the assembly on an overhead projector. Use capillary action to add a small amount of 1.0 M KCl solution between the plates. Alternately apply plus or minus 2.0 volts to produce a color change. (When the counter electrode is a wire, a lower voltage can be used; this procedure has two squares of conducting glass in the circuit and 2.0 V gives better results.) A voltage is applied to change the pixel and then the circuit is interrupted. The voltage is then reversed and the circuit reconnected. The whole process is repeated to show the persistant nature of electrochromic pixels.

If only part of the glass is coated with Prussian Blue then only that portion changes. Use three glass squares coated on the diagonal to make a multiple pixel display. Use capillary action to add a small amount of 1.0 M KCl solution between the plates. Alternately apply plus or minus 2.0 volts to individual pixels to produce a color change. A voltage is applied to change the pixel and then the circuit is interrupted. The voltage is then reversed and the circuit reconnected. The whole process is repeated to show the persistant nature of electrochromic pixels.

- Use the procedure for production of Electrochromic Prussian Blue Thin Films to produce a 150-200 nm thick layer of Prussian Blue.

- A second conducting glass square from previous lab

- Ohmeter

- Transparent tape, binder clips

- Dropper with 1.0 M KCl from previous lab

- 2.0 volt power supply. See electrical diagram

- Overhead Projector or document camera

Developed in collaboration with the

University of Wisconsin Materials Research Science and Engineering Center

Interdisciplinary Education Group | MRSEC on Nanostructured Interfaces

This page created by George Lisensky, Beloit College. Last modified June 19, 2013 .

University of Wisconsin Materials Research Science and Engineering Center

Interdisciplinary Education Group | MRSEC on Nanostructured Interfaces

This page created by George Lisensky, Beloit College. Last modified June 19, 2013 .