Overhead Projector Demonstration of Actuation of NiTi Memory Metal

NiTi actuator wires contract like muscle fiber when electrically driven. Batteries resistively heat the wire, causing it to shorten while exerting considerable force. NiTi can be incorporated into devices that are smaller, lighter, and easier to use than motors or solenoids. This demonstration shows some basic ways actuator wires may be used.

This FLEXINOL NiTi memory metal overhead projector demonstration is based on materials in the Sample Kit available from Dynalloy, Inc. The description provided here is adapted from the accompanying Dynalloy documentation. The overhead projector demonstration was developed by Eric J. Voss.

Procedure

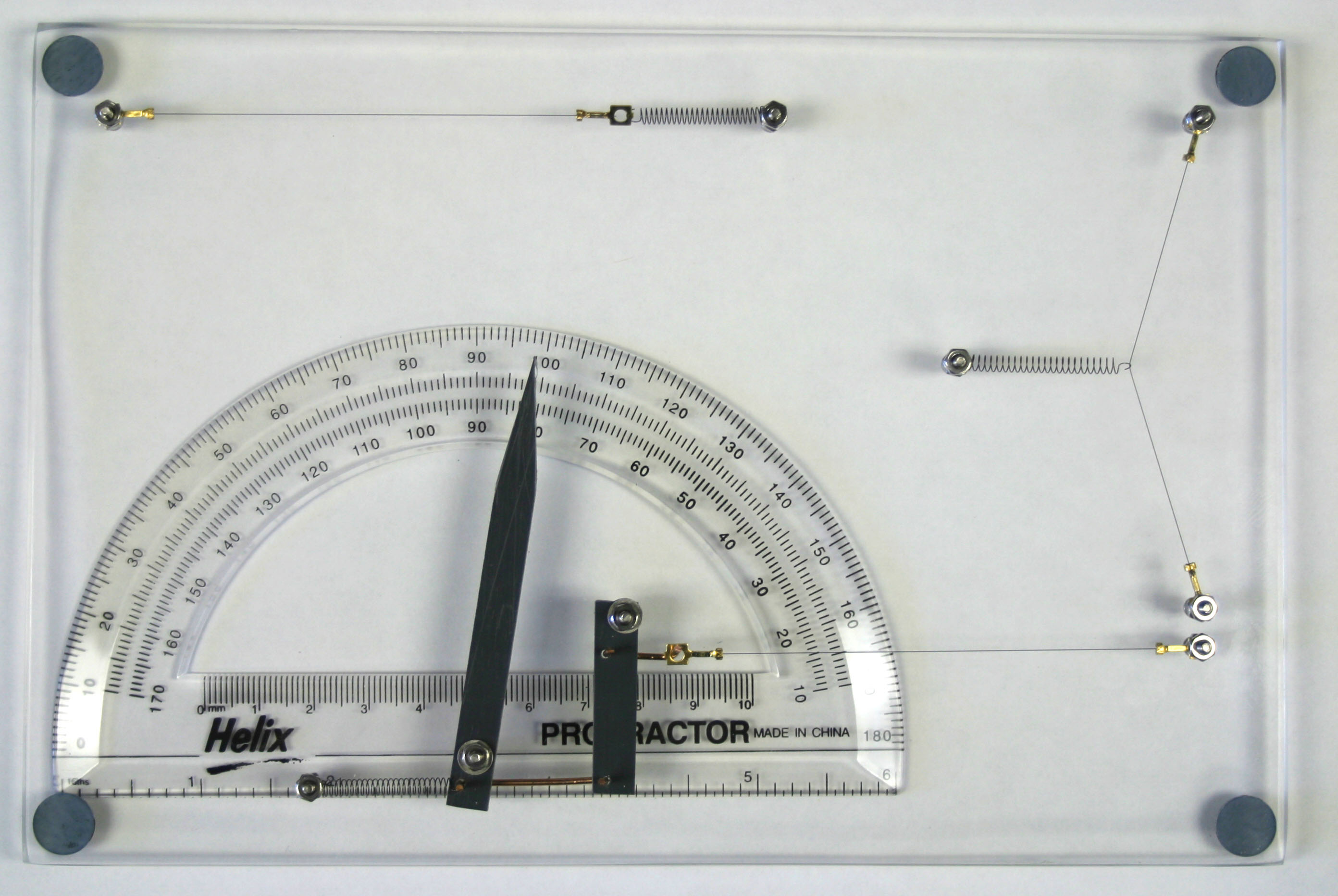

The NiTi actuator wires contract like muscle fiber when electrically driven. Electricity (in this cas provided by two AA batteries) resistively heats the wire, which causes the wire to get shorter while exerting considerable force (330 grams for a 0.006" diameter w ire). NiTi can be incorporated into devices that are smaller, lighter, and easier to use than motors or solenoids. This demonstration shows some basic ways the actuator wires may be used. Although designed to be employed on the stage of an overhead projector, this demonstration may also be presented on a tabletop with a piece of white paper underneath the Plexiglas board.Larger movie (8.3 MB) in a new window Linear Contraction. This demonstration requires the least force or strength from the NiTi wire. Force is directly related to the cross sectional area or diameter of the wire. The alligator clip is attached to the ring terminal on the left end, and the wire is activated by touching the other lead to the ring terminal on the right end, causing current to flow and the NiTi to be resistively heated. As the NiTi warms, it contracts as it passes into the austenite phase. When the current cases to flow, the wire cools and transforms back to martensite, allowing the spring to pull the NiTi wire back to its original length. In this configuration, the stroke (distance from one end of the limit of its motion to the other) is approximately 4% of the total length (0.12" change for this 3.00" wire). Right Angle Movement. This demonstration shows one way to convert some of the strength of the NiTi wire into an additional displacement. The alligator clip is attached to the ring terminal at the top end, and the wire is activated by touching the other wire to the bottom ring terminal. In this configuration, the stroke that was hardly visible in the Linear Contraction demonstration is now almost 20%. This configuration does not have a reverse bias (the geometry does not make it easier for the wire to pull as it contracts), but it would make a good latch or lock mechanism. Double Lever Movement. This demonstration produces the most force. The alligator clip is attached to the ring terminal on the right end of the actuator wire, and the wire is activated by touching the other lead to the ring terminal at the left end. The point where the NiTi wire is connected to the lever arm moves further away from the pivot point as the wire contracts, and the pointer sweeps over a range of angles on the protractor. This gives the NiTi wire more leverage as it contracts, making it easier for the actuator wire to pull as it contracts. This is called a reverse bias effect. This is very important for achieving maximum stroke over very long life (millions of cycles) and is incorporated into optimum designs in real-life applications.

Materials

Exploring the Nanoworld | MRSEC Nanostructured Interfaces

Copyright © 2013 The Board of Regents of the University of Wisconsin System.

This page created by George Lisensky, Beloit College. Last modified November 4, 2013 .

This page created by George Lisensky, Beloit College. Last modified November 4, 2013 .