Synthesis of Tris(2,2'-bipyridine)ruthenium(II) Tetrafluoroborate

The procedure was modified by Jonathan Breitzer and George Lisensky from John A. Broomhead and Charles G. Young, Inorg. Syn. 28, 338-340 (1990). The microwave procedure is from Chem. Letters (Japan) 23 (1994) 2443-2446 or J. Electroanal. Chem. 527 (2002) 33-40.

| Procedure | Wear eye protection |

Drying RuCl3 (enough for 35 preparations)

Grind about 3 grams of commercial RuCl3·3H2O in a mortar and pestle and dry in a 100°C oven for a few hours. The color will change from dark black to a dark brown.Preparation of the Ru(II) complex

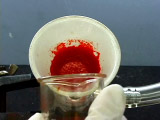

Option I: Dissolve 0.083 g (0.40 mmol) RuCl3·3H2O in 8 mL of water in a 30-mL beaker equipped with a stirbar. Add 0.188 g (1.204 mmol) 2,2’-dipyridyl and 0.44 mL of 6M NaH2PO2. Cover the beaker with a watch glass and reflux for 30 minutes. Add water if necessary to maintain the volume.Option II: Reflux a suspension of 0.083 g (0.40 mmol) RuCl3·3H2O, 0.188 g (1.204 mmol) 2,2’-dipyridyl and 10 mL 1,2-ethanediol (also known as ethylene glycol) for 3 hours on a hotplate or for 5-15 minutes in a microwave oven with condenser. The diol serves as the reducing agent. This method avoids the use of hypophosphorous acid which is a DEA List I restricted chemical. Add 0.333 g of NaBF4 dissolved in 1.5 mL of water. Let the solution cool to about room temperature and then cool in ice; crystals should form. Collect the product by suction filtration and... rinse with cold ethanol. Air dry. The [Ru(bpy)3](BF4)2 can be used to prepare an organic light emitting diode.

- Ruthenium(III) chloride trihydrate (Aldrich 20,622-9)

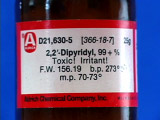

- 2,2’-Dipyridyl (Aldrich D21,630-5)

- Sodium tetrafluoroborate (Aldrich 20,221-5) Option I:

- Hypophosphorous acid, 50 wt % in water (Aldrich 21,490-6)

- Sodium hydroxide Option II:

- 1,2-ethanediol

- Ethanol

- Drying oven

- pH test paper

- Mortar and pestle, small beaker, watch glass, suction flask, Hirsh funnel

Preparation of NaH2PO2 from H3PO2 (enough for 35 preparations)

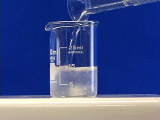

Hypophosphorous acid is monoprotic (two of the hydrogens are attached directly to phosphorus) with a pKa of 1.1. Use caution when handling. Add 10 mL of 50 % H3PO2 into a beaker containing 6 mL of water and a stirbar. Slowly add pellets of NaOH until the pH is about 6-8. This will require about 3.9 g of NaOH. The final solution is about 6 M in NaH2PO2.Developed in collaboration with the

University of Wisconsin Materials Research Science and Engineering Center

Interdisciplinary Education Group | MRSEC on Nanostructured Interfaces

This page created by George Lisensky, Beloit College. Last modified December 6, 2013 .

University of Wisconsin Materials Research Science and Engineering Center

Interdisciplinary Education Group | MRSEC on Nanostructured Interfaces

This page created by George Lisensky, Beloit College. Last modified December 6, 2013 .