Emulsion polymerization, size determination, and self-assembly of monodispersed polymethylmethacrylate (PMMA) nanospheres for photonics

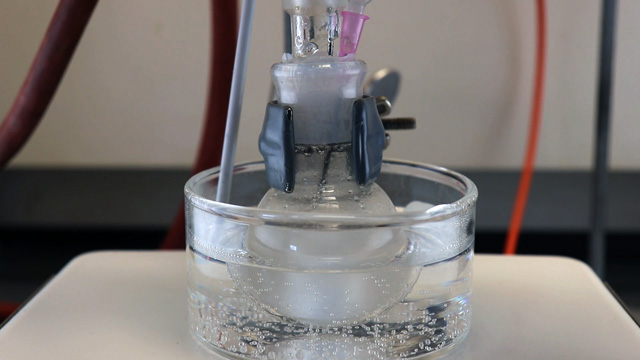

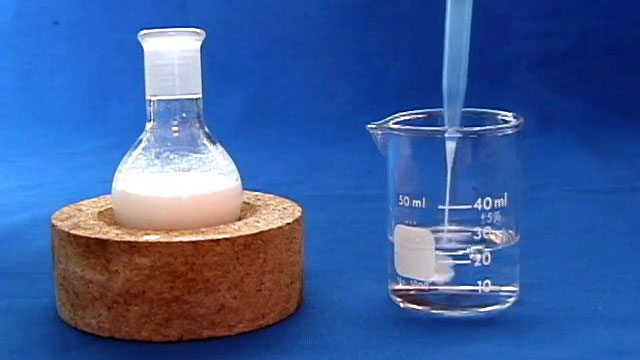

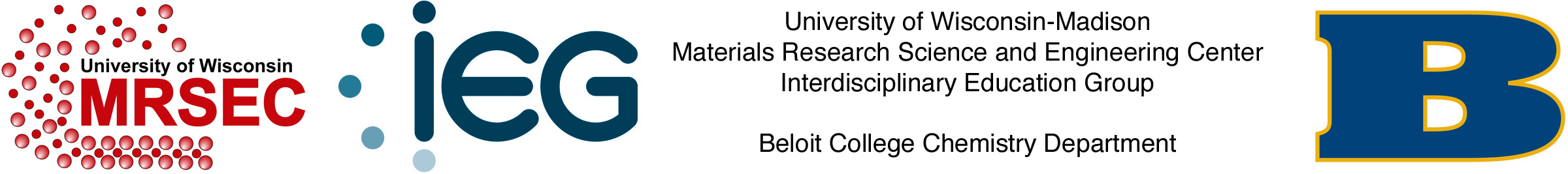

Monodispersed polymethylmethacrylate nanospheres are synthesized from the emulsion polymerization of a rapidly stirred aqueous suspension of methyl methacrylate. 2,2-Azobis(2-methylpropionamidine) dihydrochloride is a heat activated water soluble free radical initiator so the emulsion droplets polymerize starting from their outer edge.

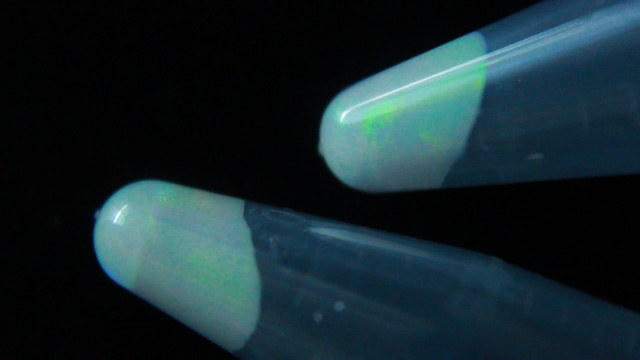

The small, uniform diameter particles should appear irridescent if they are close-packed and their size is similar to the wavelength of visible light. The size of the polymethylmethacrylate spheres can be characterized using the settling velocity and Stoke's Law, using evaporative self-assembly and visible spectroscopy measurement of the photonic band gap, and direct measurement using scanning electron microscopy. The size can also be measured after using the spheres as a template and creating a silica inverse opal.

| Procedure | Wear eye protection |

Chemical gloves recommended |

Fumehood required Fumehood required |

Synthesis (Write a purpose and method for the synthesis before starting. What are the important variables? What is the chemical reaction?)

This procedure is derived from the

Inverse Opal Photonic Crystals Laboratory Guide by R. Schroden and

N. Balakrishnan, University of Minnesota MRSEC, 2001.

Click image for larger view

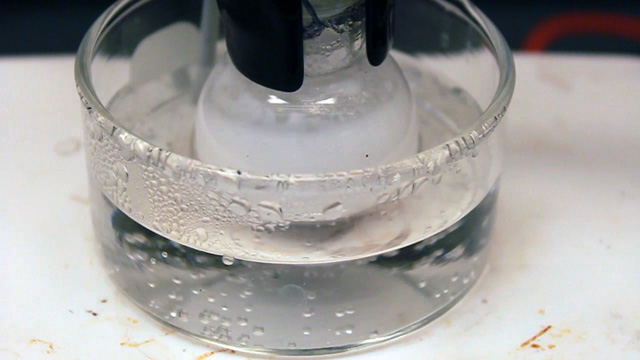

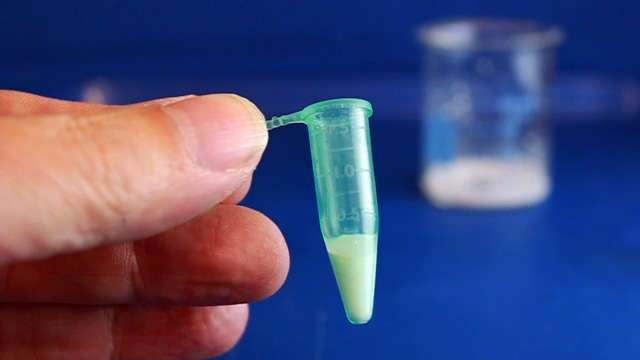

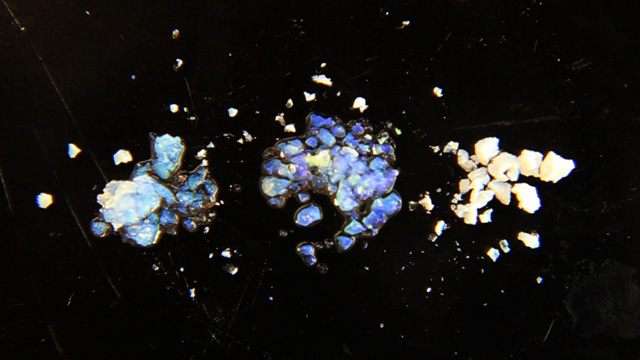

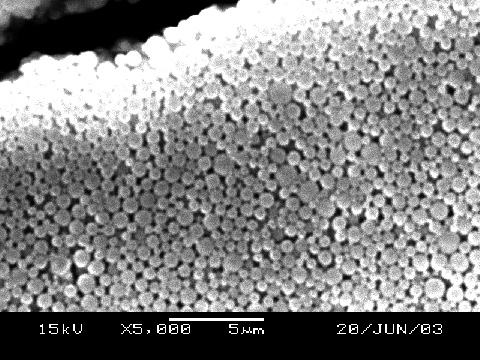

Click image for larger viewProduct without nitrogen

Click image for larger view

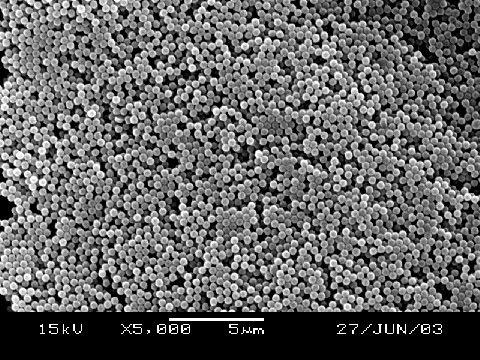

Click image for larger viewPoorly stirred product

Click image for larger view

Click image for larger viewWell-stirred product

After 40 minutes of heating, remove the condenser. There should not be a noticeable odor if the polymerization was successful. Be sure to return the Teflon joint sleeve.

After the synthesis (same lab period)

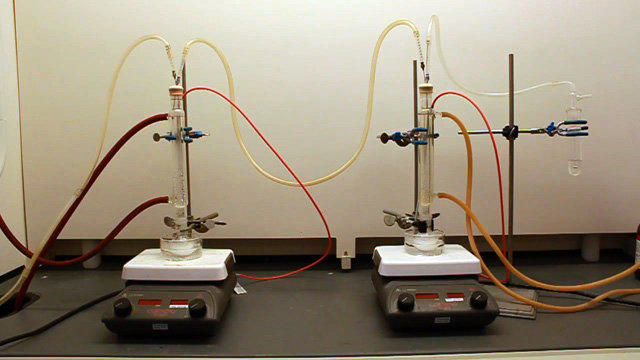

- Use the original solution to set up the Stokes Law measurements.

- Add 500µL of original solution to 20 mL water. If there is time, start the self-assembly experiment. Otherwise store the solution in a large capped centrifuge tube.

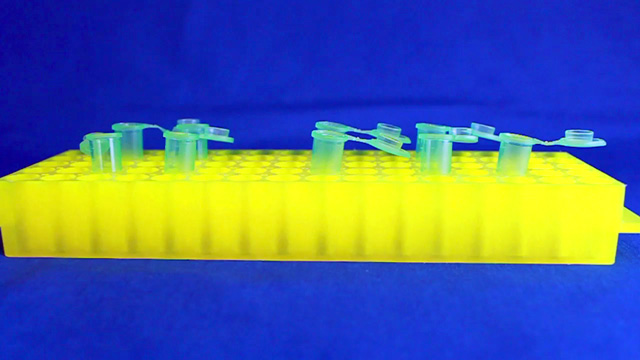

- Use the original solution to fill two labeled microcentrifuge tubes to the same depth. Save the capped tubes for the inverse opal synthesis experiments. Ideally these tubes will be centrifuged at 2000 rpm for several hours before the next lab period.

- Store any remaining original solution in a capped appropriate-size centrifuge tube for insurance.

- Glassware can be cleaned with acetone since acetone dissolves the starting material and the product.

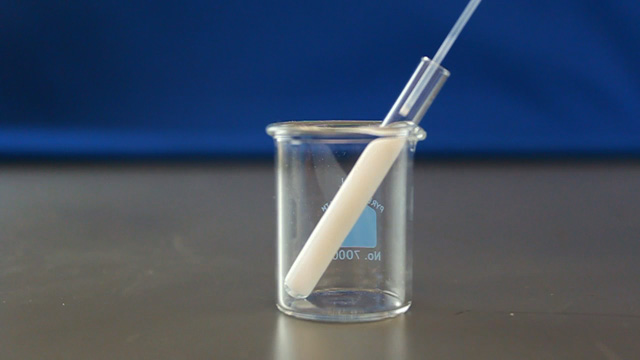

Stoke's Law Determination of Particle Size (Write a purpose and method for the Stoke's Law determination before starting.)

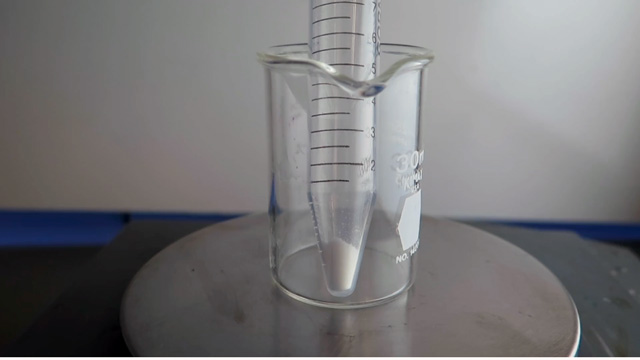

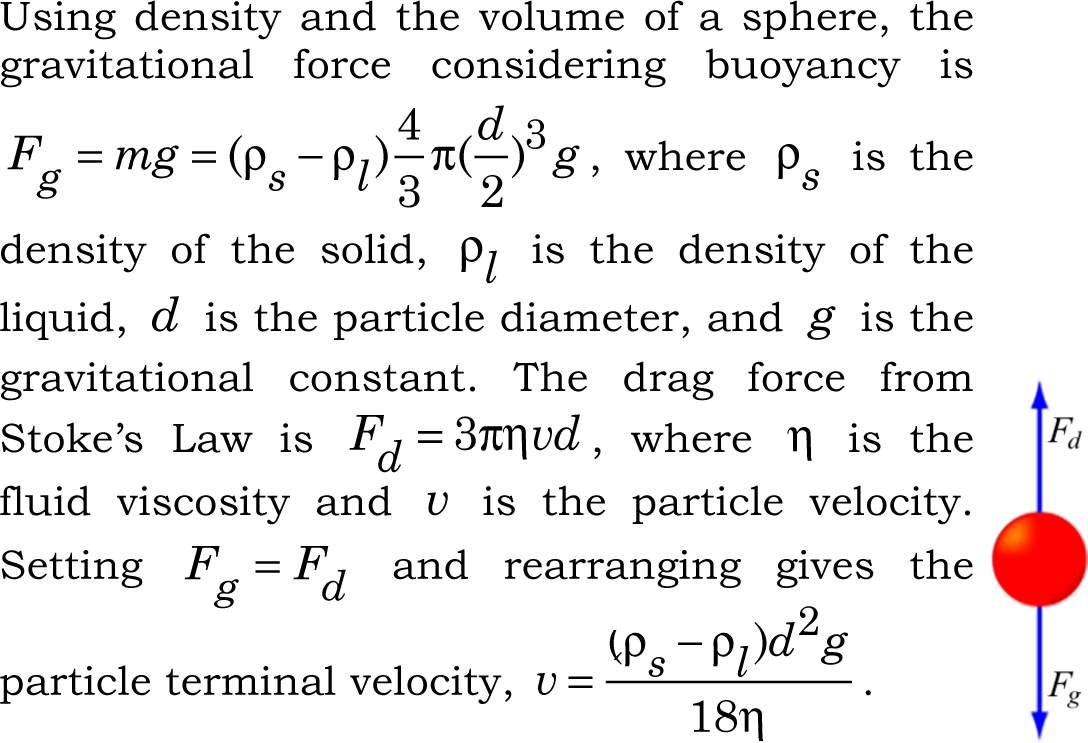

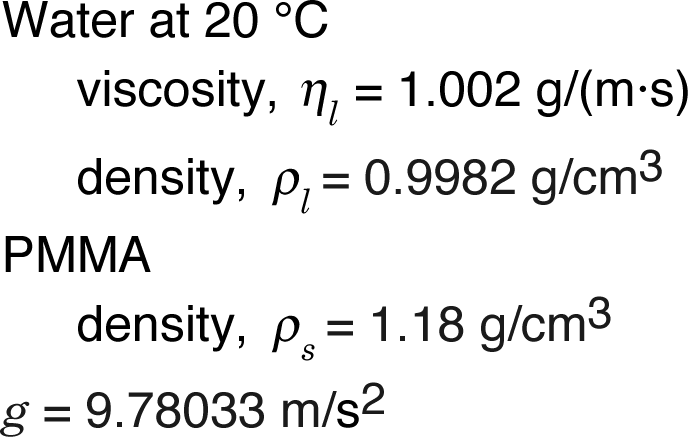

The beads will fall at their terminal velocity, which depends on their size and the known viscoscity and densities. You will measure the velocity to find the particle diameter.

Use ImageJ for measuring lengths in zoomed digital images. (Use the straight line tool to drag the length of the black tape and menu Analyze/Set Scale to tell the program the actual length of the tape, often 19mm. You can then use the straight line tool to measure lengths in real units.) Be sure all measured data is recorded in your laboratory notebook. An alternative is to print each photograph 8.5x11" and use a ruler.

Calculations and Graphs

Update your data table at least weekly. For each data point (total time in seconds, distance fallen in mm), calculate the particle diameter. Is the calculated diameter consistent?

Near the end of the experiment, plot the distance fallen in mm as a function of the number of seconds and use the slope of the linear portion as the best fit velocity. What is the overall velocity in nm/s? What is the particle size based on this velocity? What does it mean if your y-intercept is not zero?

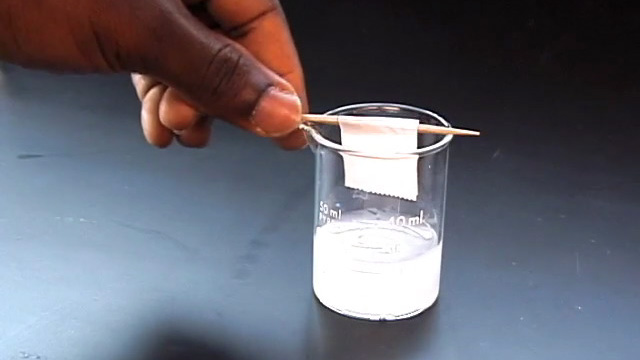

Click image for larger view

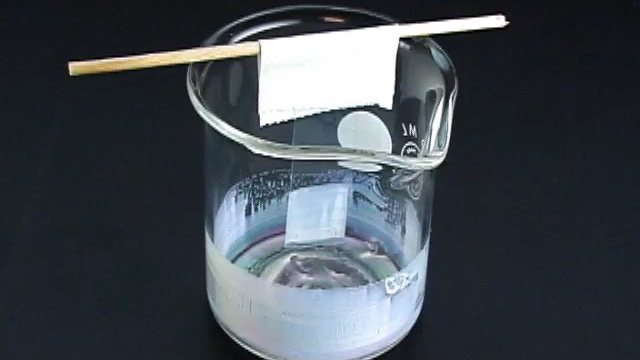

Click image for larger viewSelf-assembly

This procedure is based on work by William Schreiter, Richard Amankwah and Karen Pearson, Lawrence University (2004).

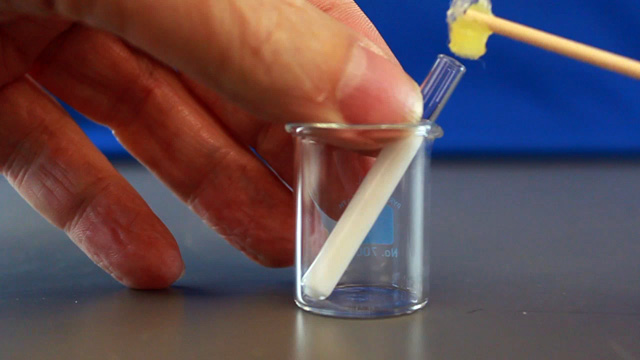

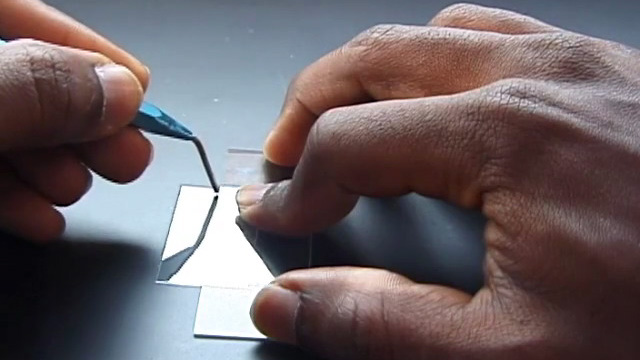

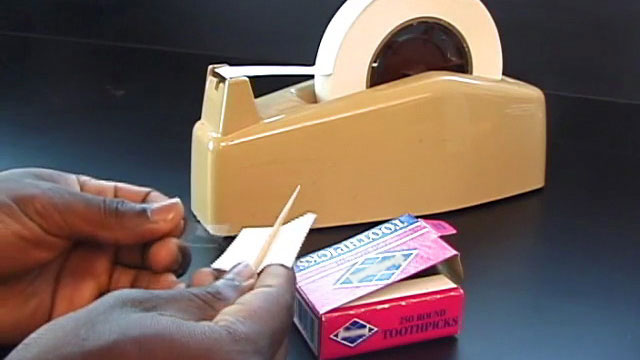

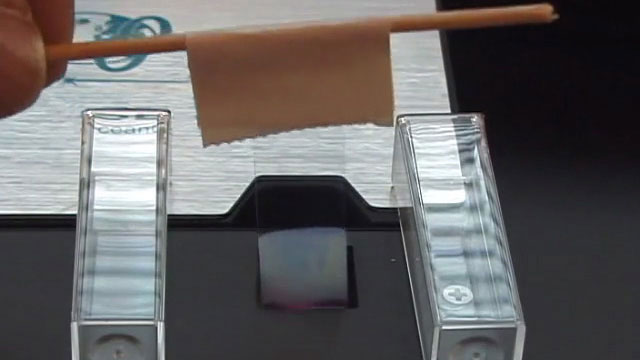

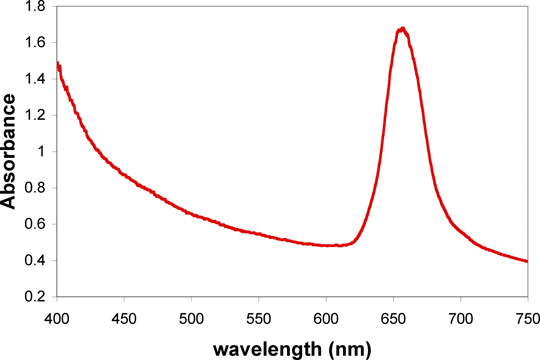

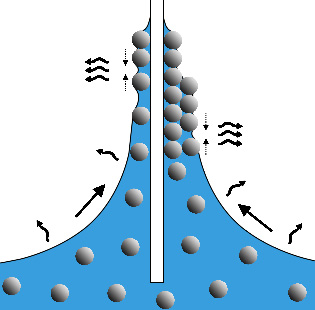

Uniform evaporation of a dilute suspension of polymer nanospheres creates a close packed layer on the surface of a glass slide suspended in the solution. The particle size can be calculated from the visible absorption maximum (called the photonic band gap) which arises by diffraction from uniformly spaced features. Dilute 500 microliters of previously prepared PMMA nanosphere solution in 20 mL distilled water. (You probably did this step right after the synthesis.) Using a diamond pencil, score and break lengthwise a large glass cover slip (22 mm x 40 mm). The piece of glass should then be able to fit into the sample compartment for visible spectroscopy measurements. Gently attach one of the glass pieces to a toothpick using tape. Write your name on the tape. Clean the glass to remove fingerprints and dust by soaking in isopropanol followed by soaking in pure water. Suspend the glass slide into the diluted PMMA nanosphere suspension you prepared earlier. If desired, more than one glass slide can be suspended in each solution as long as they do not touch each other. To promote the growth of high quality close packed layers on the glass slide, evaporate the solution in a controlled temperature environment for several days. Slightly above room temperature works well.

Observe the color of the film under reflected light conditions by holding the slide under a bright light source. Observe the color of light transmitted through the film by holding the glass slide up and looking at a bright light source through the slide. How are the colors of reflected and transmitted light related?

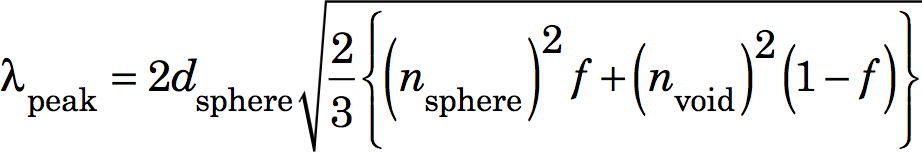

dsphere = diameter of the close packed spheres (in nm)

nsphere = index of refraction for the spheres

nvoid = index of refraction for void spaces (presumably air-filled)

f = filling fraction for a close packed structure (0.74)

SEM Determination of Particle Size (uses sample from previous step)

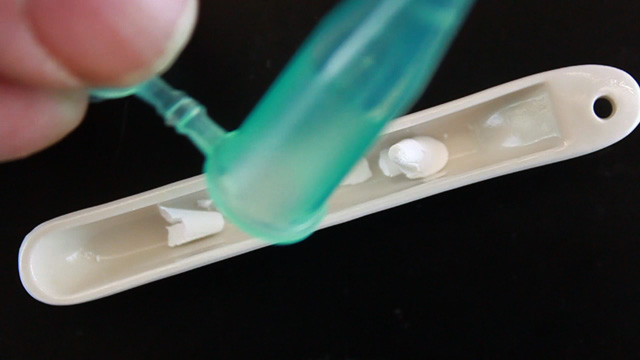

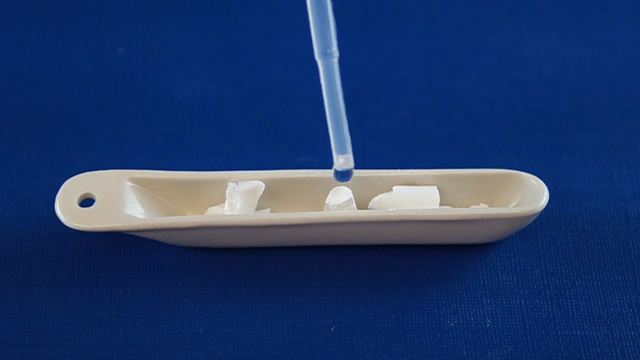

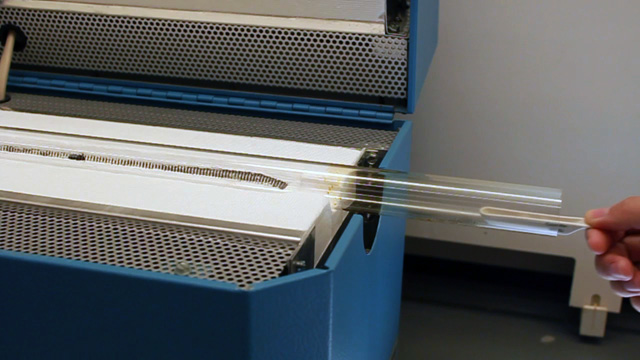

Synthesis of Inverse Opal Photonic Crystals (Write a purpose and method for the synthesis before starting. What is the chemical reaction?)

This procedure is derived from the

Inverse Opal Photonic Crystals Laboratory Guide by R. Schroden and

N. Balakrishnan, University of Minnesota MRSEC, 2001.

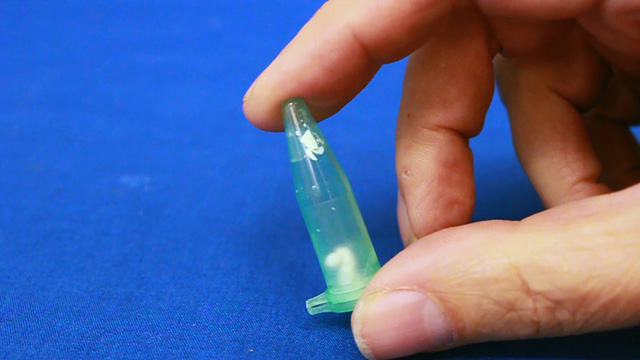

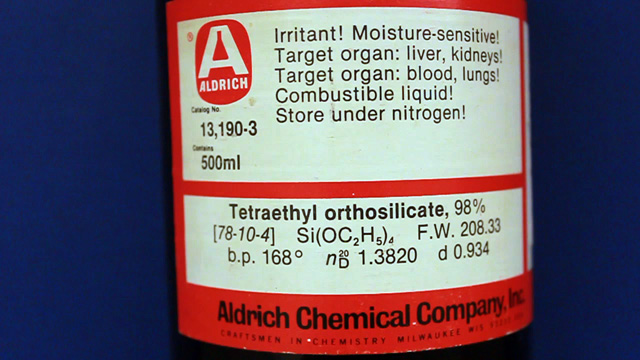

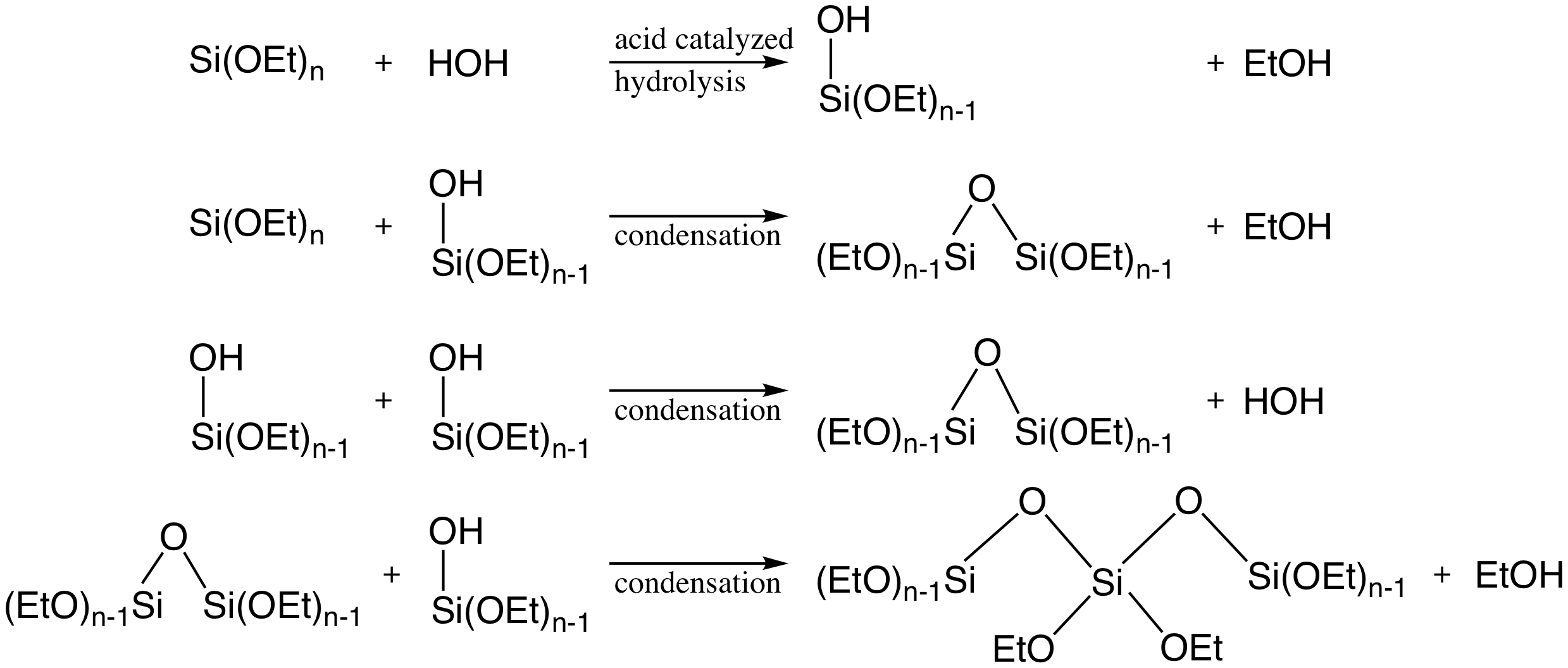

A Stöber synthesis using tetraethylorthosilicate produces a silica solid by a condensation polymerization.

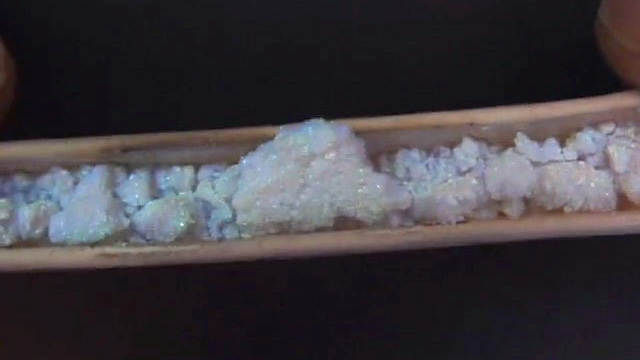

SEM Determination of Inverse Opal Hole Size (uses sample from previous step)

Inverse Opal Properties (uses sample from previous step)

- What color is your product in air? (The index of refraction of silica is 1.460 and of air is 1.000)

- Add a drop of ethanol to a small portion of your product. What color do you observe? (The index of refraction of ethanol is 1.360)

- Add a drop of toluene to a small portion of your product. What color do you observe? (The index of refraction of toluene is 1.496)

Spectra, Images and Graphs

- Did your methyl methacrylate polymerize? What observations support your answer? Using your chemical knowledge of polar/nonpolar, physical properties, and the polymerization mechanism, explain why solid spheres are expected to be produced.

- Based on your Stoke's Law measurements, what is the velocity (nanometers/second) and the corresponding diameter (nanometers) of the spheres?

- Based on evaporative self-assembly to pack spheres, what is value for the photonic band gap (nanometers or eV) and the corresponding diameter (nanometers) of the spheres? What did you use to obtain a constant temperature? How many times did you try the evaporation?

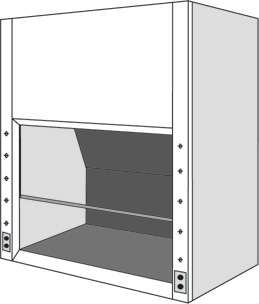

- Based on the SEM image of the opal, did the spheres close-pack and what is the diameter of the spheres (nanometers)? You should measure the diameter for more than one sphere and more than one image and take an average. Report all measured data.

- Based on the SEM image of the inverse opal, are the holes close-packed and what is the diameter of the holes (nanometers)? You should measure the diameter for more than one hole and more than one image and take an average. Report all measured data.

- Based on your hole diameter, predict the absorption wavelength for air, ethanol, and toluene. (How do you need to modify the equation for closed-packed spheres for the inverse material?) How well do your predictions match the observed colors?

- What size are the nanospheres? Do the different methods give the same results within experimental error?

Materials for Synthesis and Stokes Law

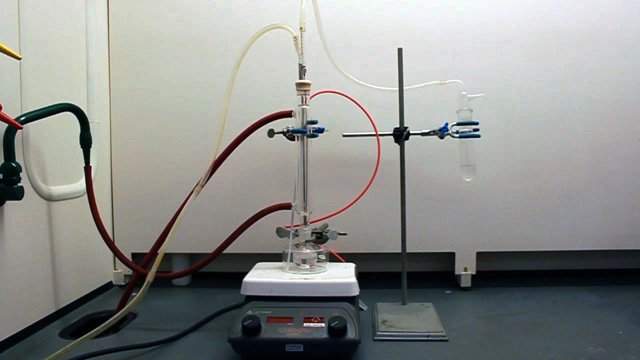

- Stirrer/hotplate. A Corning PC-420D with 6795PR temperature controller is convenient.

- 25 mL round bottom flask, condenser, crystallizing dish

- 20x10 mm oval-shaped magnetic stir bar, VWR 58949-006 or Amazon

- Reusable Teflon joint sleeves, Fisher or Amazon

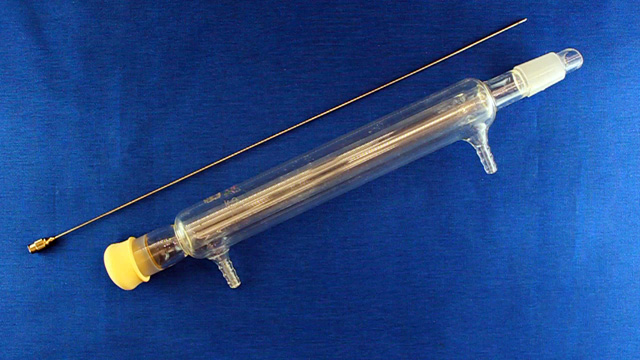

- Nitrogen gas, septum to fit condensor, gas and water hoses

- Syringe needles (one 12 inch and one 3 inch for each apparatus)

- Methyl methacrylate, Aldrich M55909

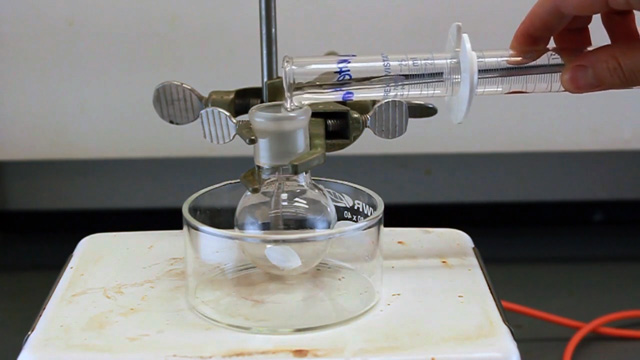

- 2,2-Azobis(2-methylpropionamidine) dihydrochloride, Aldrich 440914. Make a freshly prepared 6% stock solution of 0.12 g in 2 mL of deionized water.

- 6x50mm rimless culture tubes, VWR 47729-566 or Amazon or other small glass tubes

- Stopcock grease and sticks

- 3/4" Black electrical tape, pushpins, bulletin board, ruler, camera

Materials for Self-Assembly and Photonic Band Gap

- 30 or 50 mL beaker

- microscope glass cover slips, 22x40mm, Corning 2940-224 or 2980-224 or Aldrich CLS2980224

- diamond tip pencil, Ted Pella 54463 Diamond Scriber

- toothpicks, tape

- isopropanol, water

- oven or foam cooler and 25W incandescent bulb

- visible spectrometer

- scanning electron microscope

Materials for Inverse Opal

- 1.7 mL microcentrifuge tubes, VWR 87003-294 or Aldrich CLS3620. The product does not self-assemble in 2.0 mL Dolphin tubes.

- 2 mL (8x10x60mm) combustion boats, Coorstek 60032, Amazon

- microcentrifuge

- tube furnace

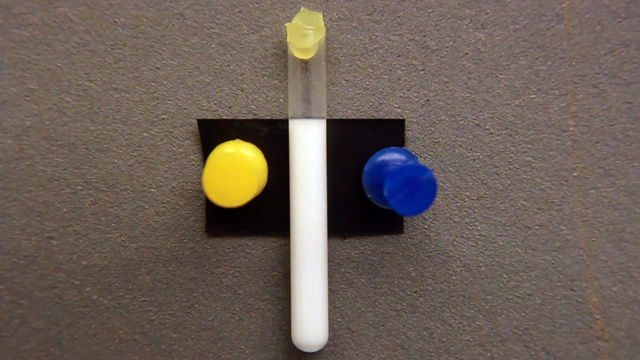

Click image for larger view

Click image for larger viewUse a tube as shown on right.

- 100% ethanol

- 25% hydrochloric acid

- tetraethylorthosilicate, Aldrich 131903

- scanning electron microscope

University of Wisconsin Materials Research Science and Engineering Center

Interdisciplinary Education Group | UW MRSEC

This page created by George Lisensky, Beloit College. Last modified February 6, 2020.