PDMS Isopropanol Microfluidics

Procedure developed by Joseph Muskin and and Mechelle Noronha from the Center for Nanoscale Chemical-Electrical-Mechanical Manufacturing Systems, University of Illinois, Urbana-Champaign.

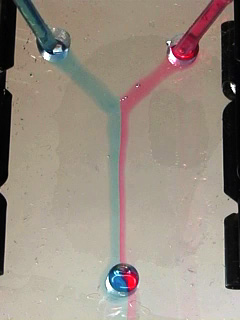

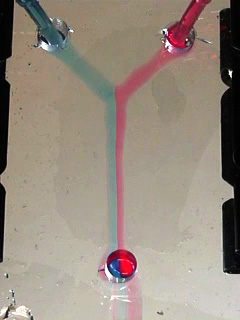

A fluidic channel is created in polydimethylsiloxane by casting the PDMS on a master made with puffy paint. PDMS is cured by an organometallic crosslinking reaction to give an optically transparent polymer. Different colored isopropanol is dispensed into the channels to observe fluid mixing.

| Procedure | Wear eye protection |

Chemical gloves required |

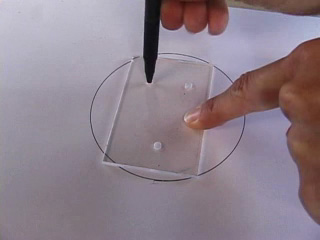

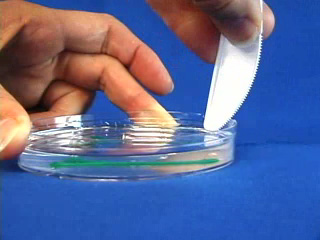

Trace a petri dish. Mark the location of the holes in the plexiglas square. Draw a Y-shape connecting the holes. Place a petri dish over the paper with the pattern. Dispense puffy paint along the pattern. Measuring the viscous PDMS liquid can be messy. Cover the work surface and the balance with aluminum foil. Wear gloves.

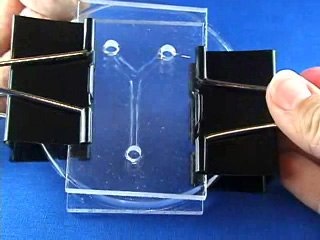

Add xxxx g of Sylgard polymer base to a plastic cup. Add xxxx g of curing agent using a disposable dropper. Thorough mixing of the PDMS components is essential for good curing. After the puffy paint has hardened, add the PDMS mixture. Evacuate to remove bubbles from the PDMS. (It will look like even more bubbles appear in vacuum but when air is reintroduced the bubbles will pop.) Alternatively waiting and gently blowing over the surface may also eliminate bubbles. Cure the PDMS at 60 degrees C for an hour. Remove the PDMS from the Petri dish. Make a plexiglas sandwich with a PDMS filling, being sure that the holes drilled through the plexiglas align with the ends of the channel. Add colored isopropanol to each channel. Do the solutions mix?

Developed in collaboration with the

University of Wisconsin Materials Research Science and Engineering Center

Interdisciplinary Education Group | MRSEC on Nanostructured Interfaces

This page created by George Lisensky, Beloit College. Last modified January 24, 2016 .

University of Wisconsin Materials Research Science and Engineering Center

Interdisciplinary Education Group | MRSEC on Nanostructured Interfaces

This page created by George Lisensky, Beloit College. Last modified January 24, 2016 .