3D Printing

Original procedure developed by Nicholas Fang and adapted by Joseph Muskin, Matthew Ragusa, Kungway Chang, and Ian McInerny from the Center for Nanoscale Chemical-Electrical-Mechanical Manufacturing Systems, University of Illinois, Urbana-Champaign. See "Three-Dimensional Printing Using a Photoinitiated Polymer," J. Chem. Educ., 2010, 87 (5), pp 512–514.

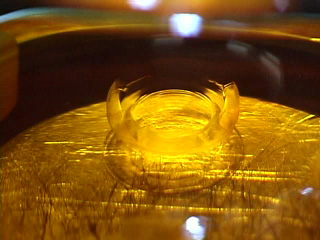

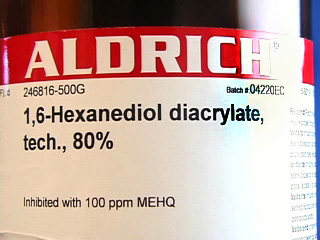

In this lithography experiment light creates free radicals from phenylbis(2,4,6-trimethylbenzoyl)phosphine oxide which induce polymerization of 1,6-hexanediol diacrylate. Light is supplied by a computer projector which shines the pattern for one layer at a time. After each layer, the elevator is slightly lowered and the process is repeated. A dye (Sudan I) is included to prevent light from penentrating much below the surface of the solution.

| Procedure | Wear eye protection |

Chemical gloves required |

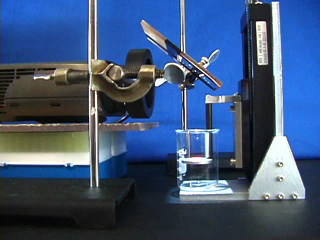

This experiment uses a computer with powerpoint and connected to a video projector, a magnifying glass, mirror, and a platform elevator. Adjust the focus so maximum sharpness occurs at the elevator platform. Fill the beaker with monomer solution to just above the level of the platform Red light is used for alignment but does not cause polymerization. For each level, shine white light in the desired pattern. Avoid long exposures that produce too much heat. Darken the screen whenever the stage is advanced. Polymer grows Continue. This movie plays 4x real time. Continue Recover solution then rinse with water. Use a razor blade to remove pieces. Small chess pieces are produced from the used pattern. Stock Materials

Equipment (See the original paper)

University of Wisconsin Materials Research Science and Engineering Center

Interdisciplinary Education Group | MRSEC on Nanostructured Interfaces

This page created by George Lisensky, Beloit College. Last modified June 16, 2013 .